It’s amazing that after so many years with radio and electronics hobbies, I had never created a DIY PCB scratch. Oh, sure, I have used printed circuit boards made by others many times. These were either purchased commercially, or fabricated to my design. But it was time to make my own. So, here goes.

Recently, I modified my 3D printer to do auto bed leveling. This required three connections and two components. I built the circuit on a breadboard and everything worked fine. Breadboards have always been used for designing and proving simple control circuits. This method of prototyping started a century ago, when hams would nail wires onto a piece of wood to try out a circuit. The pieces of wood were often a wide, flat board used in the kitchen for cutting bread.

These days, breadboards are made out of plastic, as shown above. They contain rows and columns of holes containing female pins which are connected inside the board. You can either insert components into these holes, or use jumpers to connect to components off the board. Usually, the rows at the edges of the board are used for power connections. Especially since the arrival of the Arduino, breadboards have gained popularity for prototype circuits. Once developed, the design is implemented on a PCB.

A printed circuit board (PCB) is typically a piece of rigid glass epoxy covered with a thin layer of copper. And I do mean “thin”: the layer of copper is about 0.001 to 0.004 inches thick. Typically, a chemical reaction process is used to remove the unwanted copper and leave lines or traces of copper which will carry power or signals. Each trace is terminated with a circular pad of copper. Small holes are drilled in these pads for mounting components, which are then soldered to the pads. Thus, a PCB provides both mechanical and electrical connections.

Here is how it works. You start with a piece of PCB completely covered by copper across its entire surface. Then, you draw the traces with some sort of ink that will resist the chemical reaction process called etching. The chemical reaction will remove all of the copper except that covered by the resist. Last, you clean away the resist and are left with a piece of glass with copper traces and pads on the surface.

DIY PCB – Design and Layout

Hobbyists and professionals use computer aided design (CAD) for circuits and circuit boards. There are dozens of software applications which can be used on your computer or online for professional or DIY PCB. Typically, you can just design your circuit as a schematic and the software will then apply some rules to create a PCB layout for you. This works because these CAD programs contain libraries of standard electronic components in terms of their electrical performance and their physical characteristics.

For my auto-leveling control DIY PCB, the circuit was so simple that I just drew the schematic on a piece of paper. It was also possible to draw the PCB design by hand, but I wanted to learn the whole process starting with CAD. So, I chose a fairly simple PCB CAD program called ExpressPCB.

For my auto-leveling control DIY PCB, the circuit was so simple that I just drew the schematic on a piece of paper. It was also possible to draw the PCB design by hand, but I wanted to learn the whole process starting with CAD. So, I chose a fairly simple PCB CAD program called ExpressPCB.

On the screen, I duplicated the circuit from my breadboard. Adding the connectors was easy, as the program’s library contained standard Molex pin connectors that I could place for connections to power (lower left, 2 pins), proximity sensor (lower right, 4 pins) and printer controller board (top, 4 pins).

Adding the relay proved more a challenge, for two reasons. First, the ExpressPCB library did not contain my relay. Second, the relay pins used metric spacing (millimeters) while the pin connectors were spaced in inches (or mils). So, I switched the CAD grid spacing to metric, and added the holes for the relay pins (center, 5 pins) manually.

After placing the component pads, I then added the traces between the appropriate pins. CAD programs let you control the width of traces, and diameters of pads and holes. At this point, I had my DIY PCB design completed. I printed the design and checked to make sure that all the dimensions were correct for the physical components.

DIY PCB – Toner Transfer Method

The next step was to transfer this design to the copper surface of the DIY PCB. The easiest way to do this is to use a laser printer and a household iron. When you print something with a laser printer, the machine creates characters and graphics on the paper by adding a layer of black “toner”. If you apply heat, you can transfer this toner onto the copper surface. This works best with glossy paper, such as a glossy cover page from a magazine.

Here are the steps I followed:

- Cut the DIY PCB to the right size, using a small saw or snips. Then, clean the copper surface. I used warm water and an abrasive scouring pad in the kitchen sink, followed by a wipe with acetone after it dried.

- Cut a piece of glossy magazine cover to the right size. Attach it to a piece of ordinary printer paper using blue painters tape, which is quite thin. I used the glossy cover of this week’s Economist. Make sure that you place the glossy paper correctly where you want the design to print.

- Turn off “toner saver” and make sure your printer is set for at least 300 dots per inch. Then print the design onto the glossy paper using the laser printer.

- Attach the laser printed toner image face-down on the surface of your DIY PCB. Then, simply transfer the design onto the copper using your iron at high heat. Press hard. This takes about 5-10 minutes.

- Place the PCB into a bath of warm, soapy water. Let it soak. Then, gently rub off the soaked paper with your thumb. There are many videos on the internet showing this whole process: just do a search on “PCB Toner Transfer.”

- Lastly, let the board dry. Afterwards, use acetone and a small pad or paper towel to gently rub off any remaining paper.

When you are finished, you have a copper surface with the circuit drawn in black toner. My first use of this method was nearly perfect. There was one imperfection in the 12 V power connection pad in the top left. This can be touched up with a fine point Sharpie marker. (Actually, with a steady hand, I could have drawn this whole design with a Sharpie, but using CAD was easier and more fun.)

DIY PCB – Etching the Board

There are various chemicals that can be used to etch a DIY PCB. I chose a combination of two readily available chemicals: hydrogen peroxide and muriatic acid. Hydrogen peroxide is available in a 3% solution at most drug stores. Muriatic acid (or hydrochloric acid) can be obtained at a pool supply store or various hardware stores.

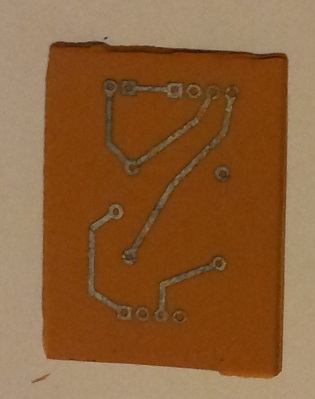

The whole etching process is with these chemicals is described here. Use caution when working with chemicals and do so in a well ventilated location. Here are the steps I followed. (Actually, in my first attempt all of the unwanted copper did not etch away properly, so I started again. I also increased the width of the traces slightly. The result is shown in the picture below.)

- Selected a small plastic container and took everything out to the garage. (The container must be plastic or glass, not metal.)

- Poured 100 ml of hydrogen peroxide into the plastic tub.

- Added 50 ml of muriatic acid.

- Placed the DIY PCB into the chemical solution and agitated it a bit with plastic tweezers. Did this for about 8 minutes.

- Remove and dry, then clean off the black toner with acetone.

- Saved the chemical solution into a glass jar for reuse in the future.

You can tell when the etching is working because the solution will turn green as the copper is etched away. You will see the copper start to dissolve at the board’s edges, and work its way in. At the end, no copper is left on the board except where protected by the toner or resist.

So, there you have it. I successfully designed and etched my first DIY PCB, and learned a lot along the way.

The next steps are drilling the holes, mounting the components, soldering, and attaching to my 3D printer. I will describe those steps in a Part 2 article soon.