While I was printing the Corner Blocks for my Mostly Printed CNC machine, I noticed that the parts were warping a bit on some of the corners. This is called PLA lifting.

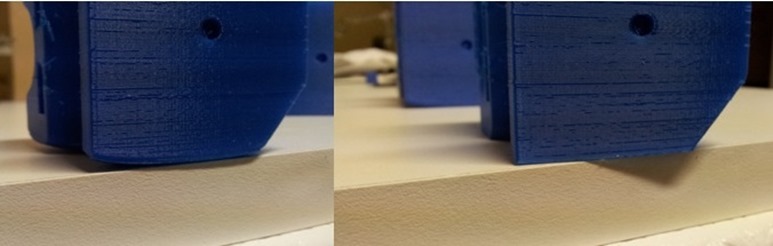

One of the best reasons for printing with PLA rather than ABS plastic is that it is not supposed to warp on the corners like ABS does. But, as you can see in the picture above left, my first MPCNC Corner Block has some PLA lifting in the corners on the lower left.

Typically, I have printed PLA on a cold (unheated) bed, in my case an aluminum plate covered with blue painters tape. Previously I have not experienced this kind of PLA lifting or warping.

PLA lifting is caused by differential temperatures in the part as it prints. When you print on a cold bed, the lower layers cool rapidly. If the plastic is only loosely adhering to the bed, the cooling causes contractions of the lower layers and this leads to PLA lifting. The corners with the most lifting were sharp, i.e. there was not very much plastic to adhere to the bed.

PLA Lifting and Bed Temperature

I was able to eliminate PLA lifting by maintaining a 50 degree temperature on the print-bed. You can see the result in the picture on the right. At first, I tried 50 degrees for the first ten plastic layers, then reduced to 40 degrees. This reduced but did not eliminate the PLA lifting. Maintaining a bed temperature of 50 degrees for the entire print did the trick.

With the cheaper imported (read Chinese) plastic filament, every roll might be a bit different. When you start a new roll, you need to measure the diameter of the plastic (sometimes it is off from 1.75 millimeters). You also need to experiment with temperatures and the extrusion multiplier in your software. My current roll of PLA works well at 222 degrees, with 228 for the first layer. I have also reduced the extrusion rate down to 88%-90%. Everyone’s mileage will vary.